Design Guide

maximum cut size and material thickness

With the addition of our new table will cut a maximum size of 2600mm by 1800mm, The plasma itself will comfortably cut anything up to and including 25mm mild steel plate.

Sheet or bar?

Get the most for what you pay, not all parts require being cut from sheet, if your part is thicker 8mm+ and less then 200mm wide, it can be cut from flat bar which can allow for greater use of the purchased material resulting in better value for money.

Clearance And Fit

While precision and accuracy of cnc profile cut plate is amazing tolerances should still be taken into consideration, there are a number of other factors that could cause issues down the line that can be easily avoided.

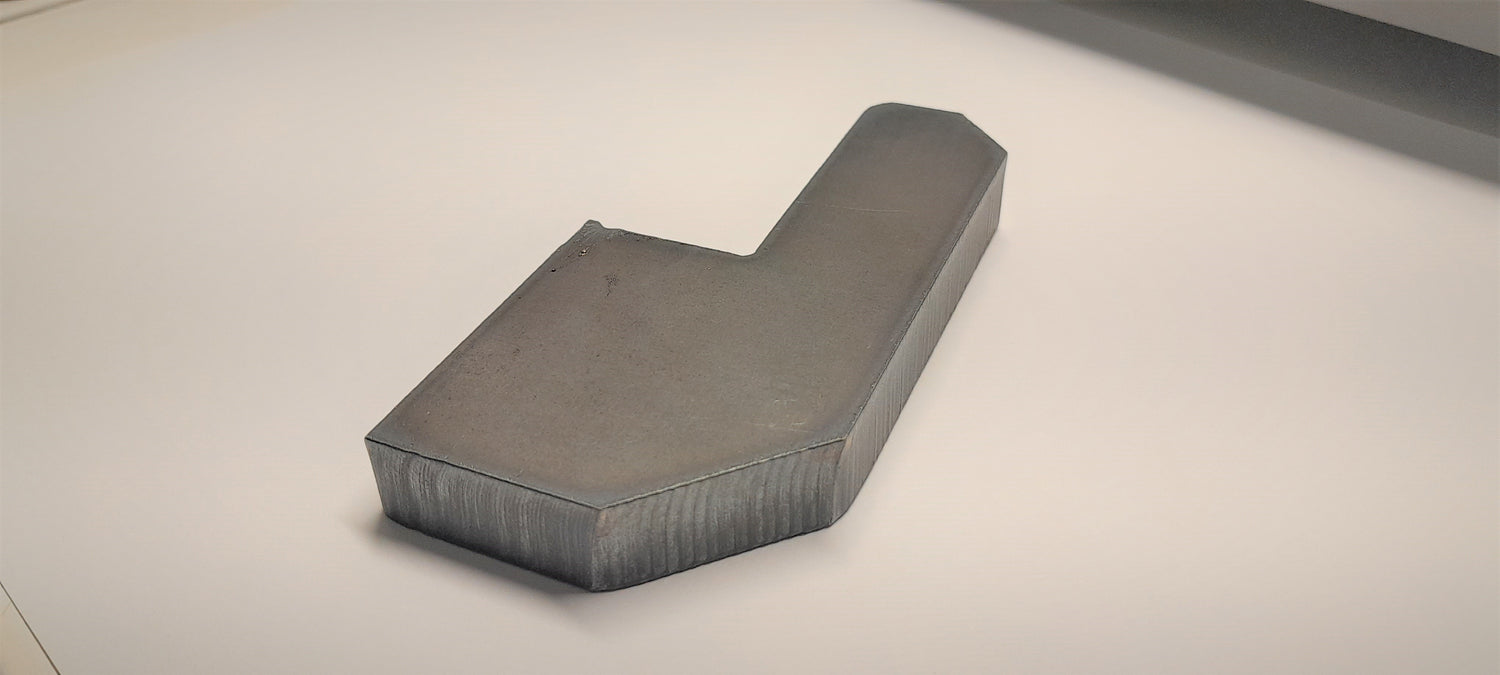

Cut Quality

This photo shows the edge of some 12mm mild steel plate while the cut face is nice and smooth, and dimensionally accurate to well below 1mm plasmas will always cut a slight bevel on one side, this is reduced to the smallest amount possible with the correct cutting setup however it is not completely unavoidable, we have measured our taper on this cut to be of less then one degree, whilst this will not be a issue in most designs just remember in the real world nothing is completely perfect and space should be given between butting up parts

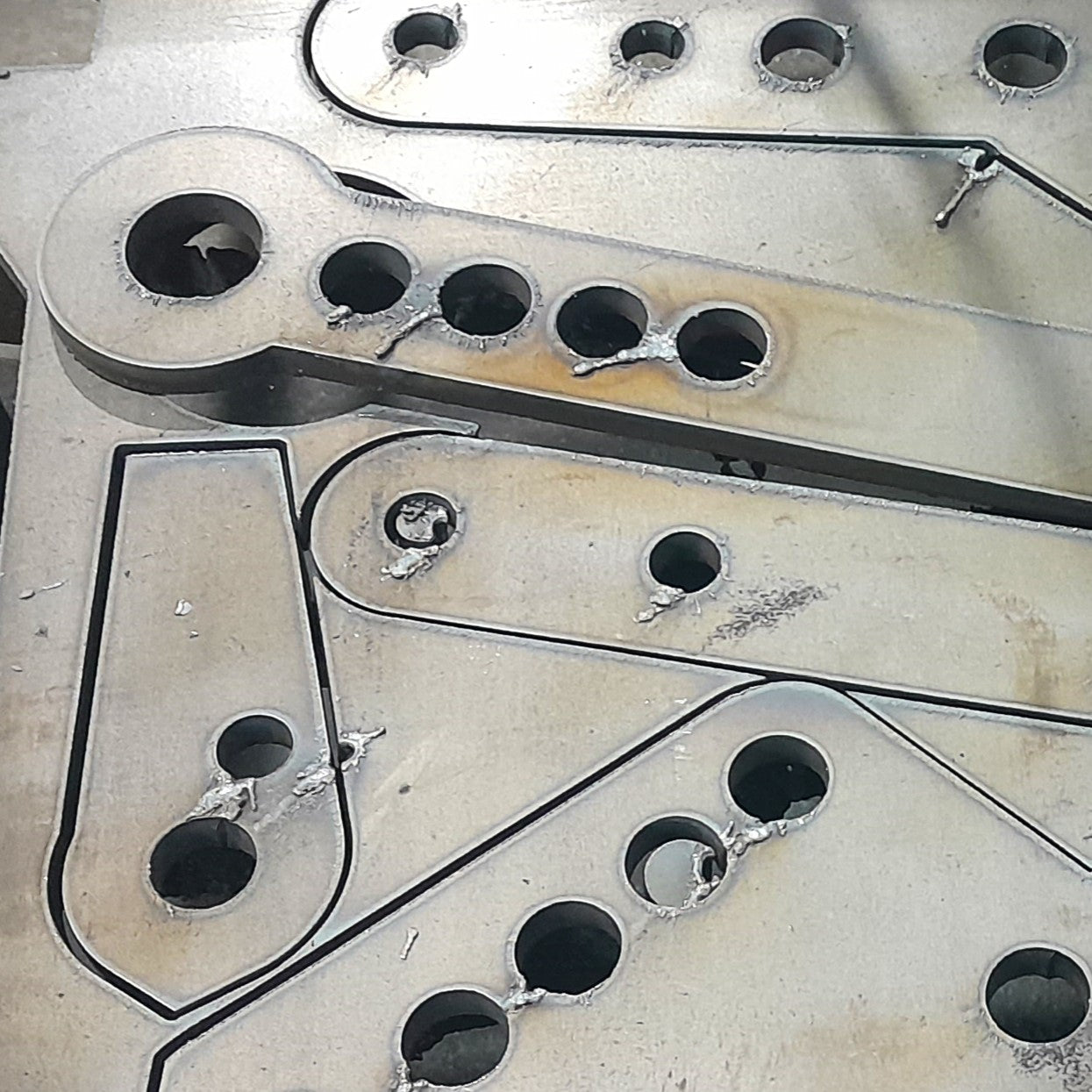

Holes

Much the same as edge quality holes can also suffer from slight taper resulting in the finish dimension being smaller from one side to the other if it is in thick plate, in plate 3-6mm this is negligible however if a hole specified at 16mm is to be cut into 16mm plate you will find it will need to be reemed after cutting for a precision fit, depending on desired fit and misalignment from multiple components in an assembly 1mm or more may need to be added to the final dimension. a general rule of thumb is to also not cut holes smaller in diameter then the thickness of plate to be used to ensure a good quality hole.

Complexity and warping

Although these parts are being plasma cut by means of cnc, complexity is still an important factor as it infulences strength of the part, cost of manufacture and risk of warping, this sign is made of 3mm alloy, and as its only relatively small still it was not at great risk of warping given that it was cut using optimal feeds so that the least amount of heat is introduced during cutting, different materials and thicknesses however will act in there own way, stainless steel for instance is far more prone to warp. Being that the cut is generaly an open profile there are little to no internal stresses in the part, however if the piece where to be constrained within a border it will want to bow.

Tab And Slot

The use of tabs and slots in your designs transforms fabrication. Interlocking tabs and slots enhance structural integrity, simplifying assembly without extra fasteners. This innovative approach, combined with plasma cutting's precision, ensures easy alignment and reduces material waste. The result is a cost-effective, efficient process that can be incorporated into most designs weather simple or complex.

Returns

More then anything CD Customs strive to deliver exceptional products at a reasonable price however it is strongly advised that you take a look at the returns policy before placing your order,returns are not in anyones best intrest, you want good parts and we want happy customers! please take a read and understand what you are getting before you purchase!